Article by Julian Austin

1. BE REALISTIC ABOUT YOUR TARGETS AND BUDGET ACCORDINGLY If you want to build a fire-breathing dragon then be prepared to fill your castle with gold. If you’ve spent thousands building your motor with the best parts money can buy then protect your investment wisely and continue to apply the same logic and approach when you decide to upgrade your fuel system. The fuel system is one of the MOST CRITICAL aspects of any build. A poor decision here could cost not only a motor but increase stress and reduce the time you spend enjoying the open road. For this reason, the correct components must be selected which are specific to your targets.

Example: Nissan R32 GTR (RB26) 1000hp @ 45psi (e85 fuel)

Fuel System Hardware (surge tank, pumps, fuel regulator, injectors, filters and fuel rail): $3450AUD

Fuel Lines & Fittings: $800-$2500 (depending on brand)

Install & Labour: $600-$1200 (depending on hourly rate and effort required)

When calculated, the total figure may sound like a large sum of money however, keep things in perspective. Other than regular maintenance of your injectors and fuel filter elements every six (6) months, this is a one-off cost and, if installed correctly, will ensure you won’t be forced to spend anything further for many years to come: the average life span of a fuel pump is 5-7 years and as for the surge tank, we offer a lifetime structural warranty. So my advice is, develop a realistic Project & Budget Plan. Yes, do your research, speak with professionals and write it down on a piece so you are aware of the costs involved.

2. HOW TO DETERMINE THE CORRECT FUEL SYSTEM COMPONENTS Understandably, each engine and type of fuel has different consumption and efficiency characteristics. A rotary engine for example has a longer operating cycle than a reciprocating engine, and thus requires substantially more fuel. Similarly, ethanol based fuels carry less energy per unit volume than gasoline and despite a higher MON octane rating, more fuel is required to match the efficiency of pump gas.

In order to determine the correct components we need to first calculate the rate of fuel consumption. The Brake Specific Fuel Consumption or the BSFC formula, with the correct inputs and equations, will assist with this determination. We measure the BSFC is terms of litres per hour of fuel required to support X engine with Y horsepower using Z fuel. At this point you will have a few questions: a) “So where does this leave me?” b) “How can I ensure the BSFC calculator I’ve found online is accurate?; and c) “How on earth does this relate to fuel regulator, fuel pump, injector and surge tank selection?”

Unfortunately, it is impossible to create a set of rules or guiding principles that would serve a useful purpose. Blanket statements about which regulator is best or that a certain injector will be most suitable would be nothing more than a generic and irresponsible approach that could lead to disastrous results. What differentiates Aftermarket Industries from other companies is our knowledge and experience. We’ve developed what I believe is the most comprehensive and accurate BSFC calculator which comprises of almost ten (10) years of data to ensure accuracy to within 3% – 5%. You can access this online here: http://www.aftermarketindustries.com.au/fuel-system-calculator

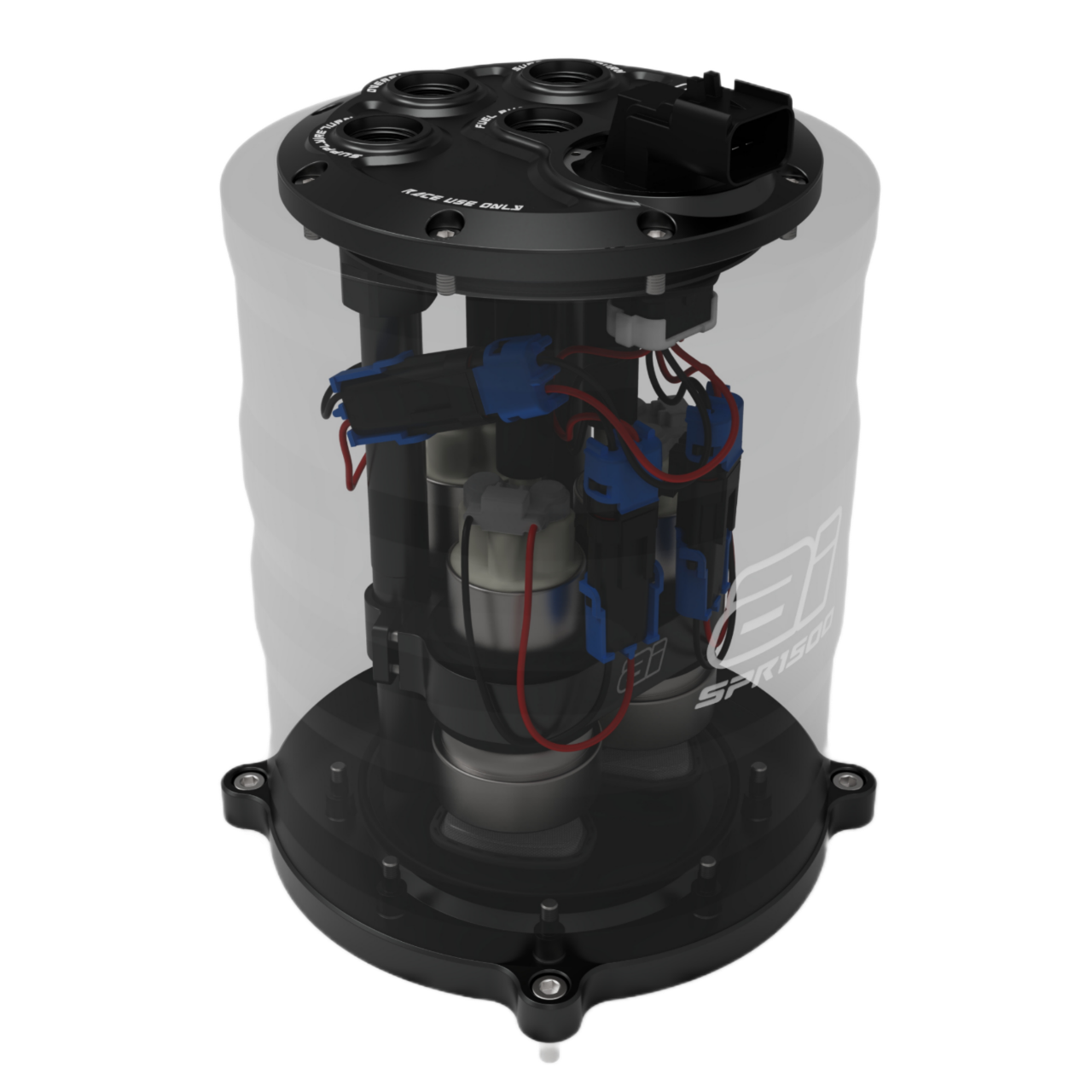

Once received, we will then analyse the results and access each individual project requirements against component performance tables. For instance, if a customer requires 700lhr (e85) of fuel at a maximum operating combined fuel pressure of 75psi, we will not only match this with the correct combination of fuel pumps, surge tank, injectors and other components, but also ensure minimum redundancy or safety thresholds are satisfied. In other words, we design a complete solution designed to work holistically rather than separate individual components.

Here are some basic questions to consider:

- Is the fuel pressure regulator able to support the maximum fuel pressure target?

- Is the return port of the fuel pressure regulator large enough to ensure the fuel supply is not constricted?

- Is the fuel filter flow rated and will it support the flow of fuel on the line it is installed?

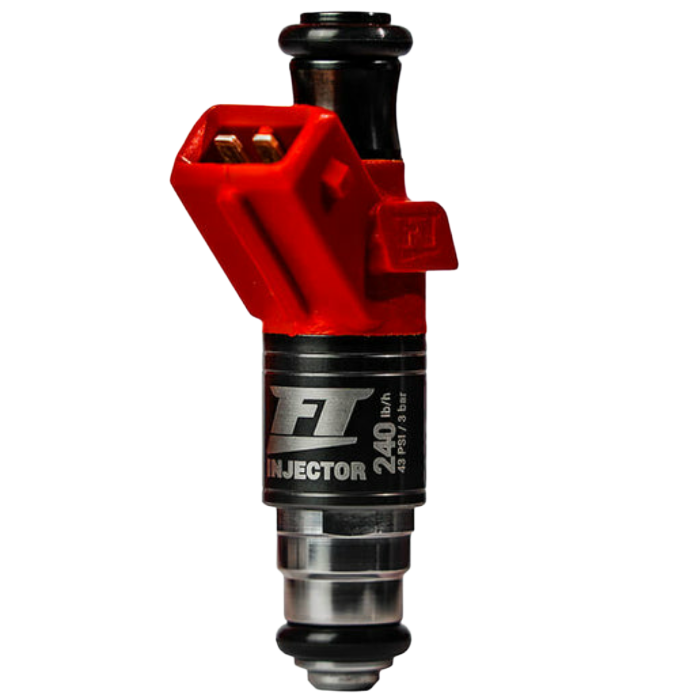

- What is the duty cycle of the injectors at the target fuel pressure and is there enough leniency for potential future upgrades?

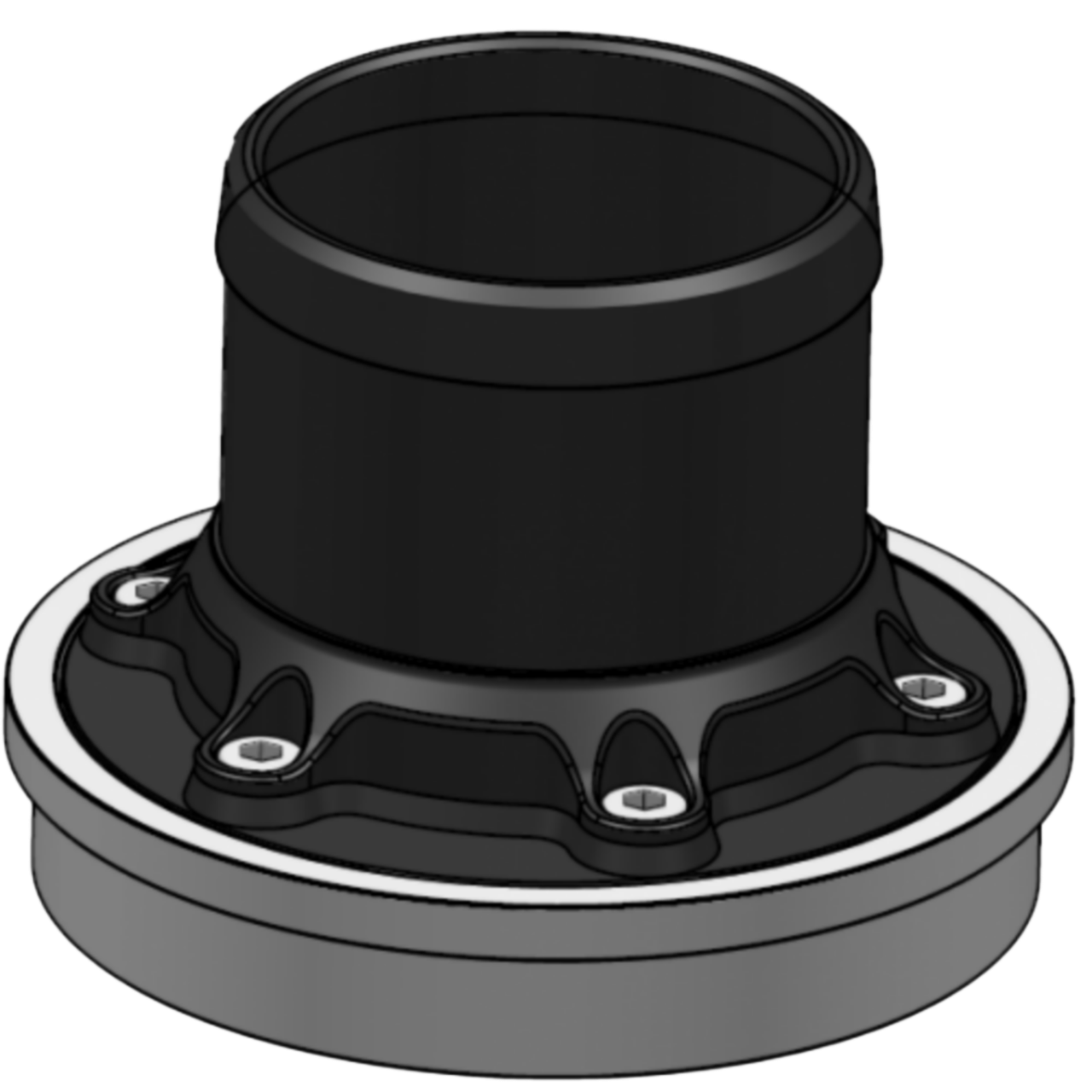

- Is the surge tank capacity sufficient to support the intended driving application at WOT for the target time when factoring in pre-pump and returning fuel inputs?

- What is the fuel pump output and efficiency at the target fuel pressure?

3. IN-TANK UPGRADE VS EXTERNAL SURGE TANK So now that you’ve determined the correct BSFC, the next item for discussion is without doubt the main sticking point for many performance auto enthusiasts and directly related to my first point. It’s a sticking point because for some the idea of installing an external fuel system is out of the question for reasons such as “I don’t want to spend that much money”, “I don’t want a surge tank in my boot because I don’t want any noise or the smell fuel inside the car” or “I have safety concerns”. These are all reasonable reasons or concerns, but are they realistic or even true? I will discuss these below.

“I don’t want to spend that much money”: The reality is that if there’s an “easier” option its human nature to take the most direct path. This may be true when walking from A to B but if the destination is Z then you’ve not achieved your objective. What then are my thoughts with respect to in-tank or drop-in replacement fuel systems vs an external surge setup? Your factory fuel tank, fuel pump, fuel pump assembly, fuel lines, regulators… (you get the picture) was designed by a highly skilled engineer who was given set variables and instructions at the time of the vehicle design was conceived. As a result, from an aftermarket performance perspective, there will always be constraints and challenges when you decide to increase horsepower output. For instance, a factory fuel pump hanger which features a fuel bucket assembly may have a total displaced fuel capacity of 1.5 litres. If it’s a newer model or you tank has a “hump” in the middle (left bank / right bank) it may also feature a venturi tube. The venturi tube works to siphon fuel from other sections of the fuel tank to ensure the factory fuel pump bucket is always full. Herein lays two key challenges. Firstly, the venturi system is based on the flow characteristics of the factory fuel pump and any changes to the fuel pump assembly will adversely affect or reduce its function. Secondly, the factory fuel pump bucket proportions and factory flange are fixed and cannot be increased or modified.

The factory venturi tube can be manipulated to a certain extent and we’ve discovered how to do this effectively and a process we have only shared with our customers until this point. I plan to write an article about this shortly.

If we then turn our attention to the second challenge, let say we wanted to design a new billet dual pump in-tank replacement kit for a poplar model. Irrespective of our experience and knowledge, are design will be based on the OEM dimensions. The addition of a 2nd pump with a dual supporting fuel pump bracket will undoubtedly reduce the 1.5 litres to below 1 litre. Combine this with the fact that the siphoning system is now unable to the sufficiently maintain fuel levels at the previous rate and you’re in a world of trouble particularly if you’re under Wide Open Throttle (WOT) for an extended period of time: we’ve tested this theory both using sophisticated simulation software, actual prototypes and in real world scenarios.

The simple fact is that an in-tank duel fuel pump upgrade may work great on a stationary vehicle on the dyno with a full tank of fuel and this may be equally true for everyday driving. However, an in-tank solution will never offer protection against fuel surge or fuel starvation especially when the fuel tank volume is low and when lateral or longitudinal forces are applied (acceleration and hard concerning). Our customers build their cars to enjoy them both on the street and the occasional off-street meetings and at popular events such as Powercruise and Power Play.

Another concern I will raise with respect to in-tank fuel system upgrades is the lack of consideration of other components at the time of the upgrade. Thinking that the factory fuel lines, regulator and the factory fuel filter will cope over time with the significant increase in flow, pressure, load and stress without creating further issues lacks any real logic. I’ve seen the results of a factory fuel filter disintegrate because the customer decided to replace the factory 150lhr fuel pump with a single Walbro 460 fuel pump. The factory filter simply was not designed to support such flow, it broke apart, the filter particles flowed through the fuel lines and blocked the injectors and this lead the major engine failure all because the customer decided against the effort and costs involved.

So what’s my point I hear you ask? There are no short cuts. If you want to utilise a drop-in system with either a higher flowing single pump or dual pumps then you MUST upgrade ALL other supporting components. So in terms of the costs associated with a drop-in system vs an external surge tank, they are comparable. So the real question then is “what’s holding you back from upgrading to a surge tank system that offers you the peace of mind in all driving scenarios; street, track, drags, drift?”

There will be some of you who read this who have already purchased or considering a drop-in system. I say this, I only offer the truth based on our experience and R&D efforts. Unfortunately, a large portion of our projects involve replacement of previous fuel systems that were not correctly designed or adequately matched to the customers’ requirements. So ensure you make your requirements clear to the manufacturer or workshop before you commit to any fuel system upgrade and consider all the necessary changes and potential impact on other factory components your intended solution will have.

“I don’t want a surge tank in my boot because I don’t want any noise or the smell fuel inside the car” or “I have safety concerns”: As mentioned earlier these are very reasonable and legitimate concerns for any customer but the truth of the matter is that with the current technology, engineering and manufacturing processes these concerns are also very easy to address.

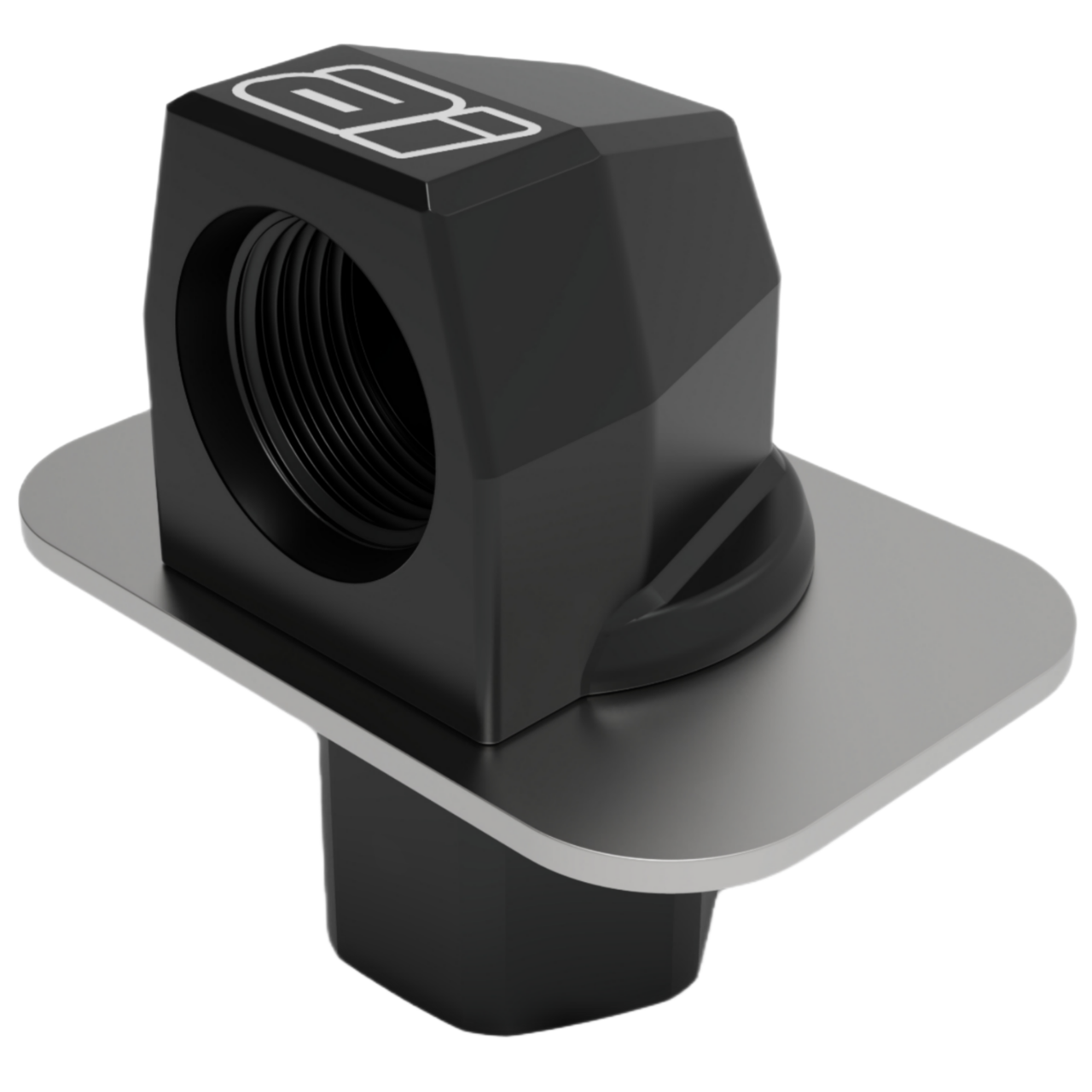

Noise is generally produced by two factors: a) fuel pump operation/design and b) vibration / metal-to-metal contact. Unlike all other aftermarket fuel systems, our systems are silent in operation due to our unique sound dampening bio-fuel compatible rubber inserts.

Fuel smell only occurs where the material is not anodised. All components used with our surge tank kits are anodised inside and out.

Safety is another factor we’ve addressed with our products and something I personally take very seriously. Every product we design is stress tested against the best practice engineering principles. For example, our SP044, SPR400, SP800 and SP1200 surge tank kits will withstand between 200,000n to 400,000n of stress distortion load and will not fail. That’s equivalent to 200km/hr impact by a MACK TRUCK. To prove this point, last year the Tristan Catford Racing Mitsubishi Evo 8 lost its brakes at 170km/hr and hit a tree whilst on the final stage of the Australian Tarmac Rally Championship. The car was totalled and the couple were lucky to survive with minimal injuries and now doing well. The Evo was equipped with our SP044 which also survived unscathed. I often hear that our kits are expensive or over-engineered. These are the type scenarios that justify our approach and investment into R&D. Safe, noise free, no smell, not only looks cool but protects your investment.

Upgrading to a surge tank is the only real choice for anyone serious about their build. Speak to us today to schedule a project meeting either in person or over the phone to discuss your specific requirements: 02 8001 6650